This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

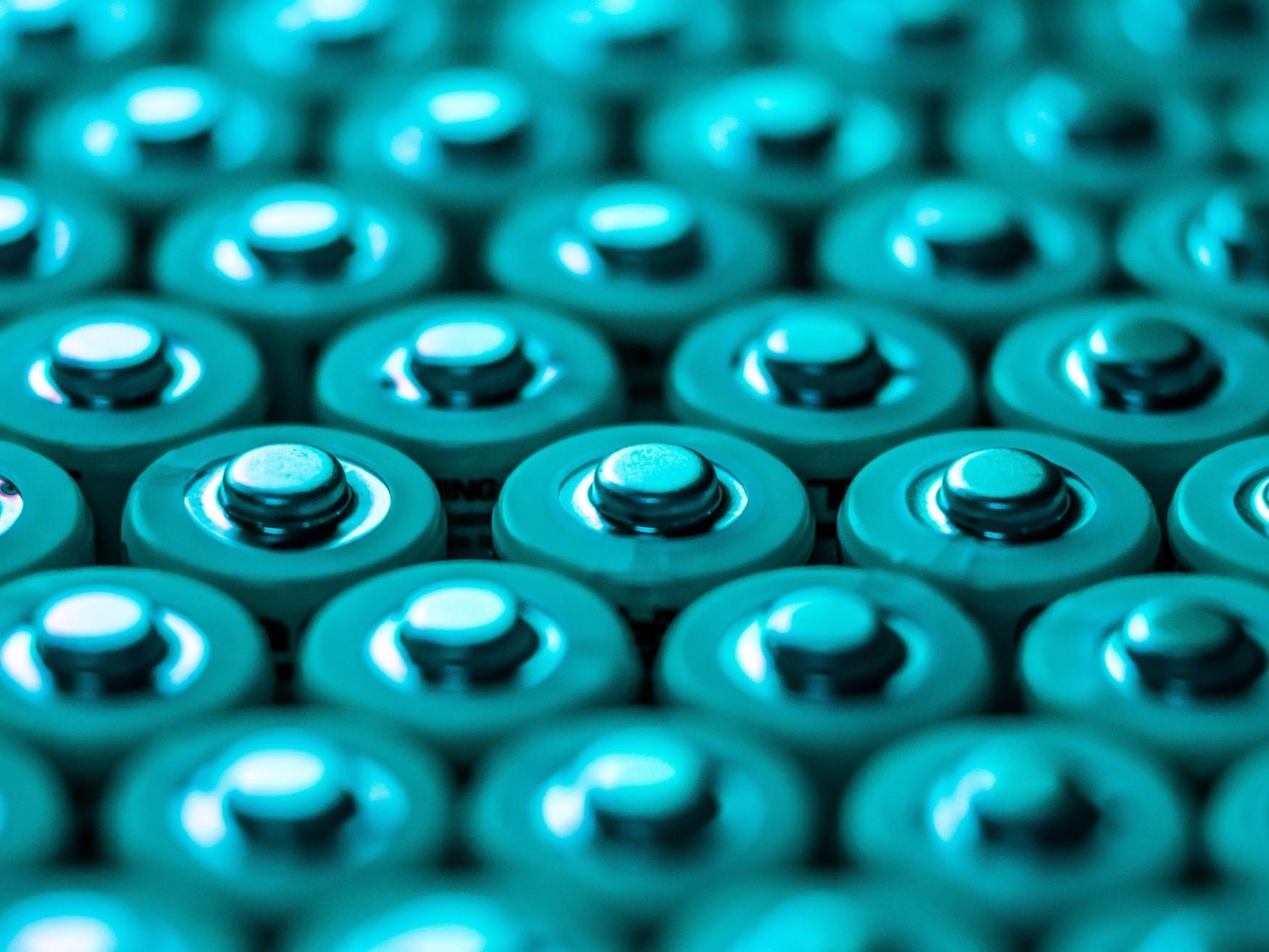

A battery pioneer has invented a new kind of battery that is 90 per cent cheaper to produce than standard lithium-ion batteries, and potentially much safer.

Hideaki Horie – who has worked on battery technology since 1990 and led Nissan’s development of the Leaf electric car – discovered a way to replace the batteries basic components in order to speed up and simplify the manufacturing process.

“The problem with making lithium batteries now is that it’s device manufacturing, like semiconductors,” Mr Horie told The Japan Times. “Our goal is to make it more like steel production.”

Manufacturing the new batteries is significantly simplified by replacing the metal-lined electrodes and liquid electrolytes typically found within lithium-ion units with a resin construction.

Mr Horie said the new construction method used by his Tokyo-based company APB Corp is as easy as “buttering toast”.

Lithium-ion batteries are used in everything from smartphones to electric cars, having first been commercialised nearly three decades ago by Sony.

Created with Sketch.

Created with Sketch.

1/25 Gun-toting humanoid robot sent into space

Russia has launched a humanoid robot into space on a rocket bound for the International Space Station (ISS). The robot Fedor will spend 10 days aboard the ISS practising skills such as using tools to fix issues onboard. Russia's deputy prime minister Dmitry Rogozin has previously shared videos of Fedor handling and shooting guns at a firing range with deadly accuracy.

Dmitry Rogozin/Twitter

2/25 Google turns 21

Google celebrates its 21st birthday on September 27. The The search engine was founded in September 1998 by two PhD students, Larry Page and Sergey Brin, in their dormitories at California’s Stanford University. Page and Brin chose the name google as it recalled the mathematic term 'googol', meaning 10 raised to the power of 100

3/25 Hexa drone lifts off

Chief engineer of LIFT aircraft Balazs Kerulo demonstrates the company's "Hexa" personal drone craft in Lago Vista, Texas on June 3 2019

Reuters

4/25 Project Scarlett to succeed Xbox One

Microsoft announced Project Scarlett, the successor to the Xbox One, at E3 2019. The company said that the new console will be 4 times as powerful as the Xbox One and is slated for a release date of Christmas 2020

Getty

5/25 First new iPod in four years

Apple has announced the new iPod Touch, the first new iPod in four years. The device will have the option of adding more storage, up to 256GB

Apple

6/25 Folding phone may flop

Samsung will cancel orders of its Galaxy Fold phone at the end of May if the phone is not then ready for sale. The $2000 folding phone has been found to break easily with review copies being recalled after backlash

PA

7/25 Charging mat non-starter

Apple has cancelled its AirPower wireless charging mat, which was slated as a way to charge numerous apple products at once

AFP/Getty

8/25 "Super league" India shoots down satellite

India has claimed status as part of a "super league" of nations after shooting down a live satellite in a test of new missile technology

EPA

9/25 5G incoming

5G wireless internet is expected to launch in 2019, with the potential to reach speeds of 50mb/s

Getty

10/25 Uber halts driverless testing after death

Uber has halted testing of driverless vehicles after a woman was killed by one of their cars in Tempe, Arizona. March 19 2018

Getty

11/25

A humanoid robot gestures during a demo at a stall in the Indian Machine Tools Expo, IMTEX/Tooltech 2017 held in Bangalore

Getty

12/25

A humanoid robot gestures during a demo at a stall in the Indian Machine Tools Expo, IMTEX/Tooltech 2017 held in Bangalore

Getty

13/25

Engineers test a four-metre-tall humanoid manned robot dubbed Method-2 in a lab of the Hankook Mirae Technology in Gunpo, south of Seoul, South Korea

Jung Yeon-Je/AFP/Getty

14/25

Engineers test a four-metre-tall humanoid manned robot dubbed Method-2 in a lab of the Hankook Mirae Technology in Gunpo, south of Seoul, South Korea

Jung Yeon-Je/AFP/Getty

15/25

The giant human-like robot bears a striking resemblance to the military robots starring in the movie 'Avatar' and is claimed as a world first by its creators from a South Korean robotic company

Jung Yeon-Je/AFP/Getty

16/25

Engineers test a four-metre-tall humanoid manned robot dubbed Method-2 in a lab of the Hankook Mirae Technology in Gunpo, south of Seoul, South Korea

Jung Yeon-Je/AFP/Getty

17/25

Waseda University's saxophonist robot WAS-5, developed by professor Atsuo Takanishi

Rex

18/25

Waseda University's saxophonist robot WAS-5, developed by professor Atsuo Takanishi and Kaptain Rock playing one string light saber guitar perform jam session

Rex

19/25

A test line of a new energy suspension railway resembling the giant panda is seen in Chengdu, Sichuan Province, China

Reuters

20/25

A test line of a new energy suspension railway, resembling a giant panda, is seen in Chengdu, Sichuan Province, China

Reuters

21/25

A concept car by Trumpchi from GAC Group is shown at the International Automobile Exhibition in Guangzhou, China

Rex

22/25

A Mirai fuel cell vehicle by Toyota is displayed at the International Automobile Exhibition in Guangzhou, China

Reuters

23/25

A visitor tries a Nissan VR experience at the International Automobile Exhibition in Guangzhou, China

Reuters

24/25

A man looks at an exhibit entitled 'Mimus' a giant industrial robot which has been reprogrammed to interact with humans during a photocall at the new Design Museum in South Kensington, London

Getty

25/25

A new Israeli Da-Vinci unmanned aerial vehicle manufactured by Elbit Systems is displayed during the 4th International conference on Home Land Security and Cyber in the Israeli coastal city of Tel Aviv

Getty

1/25 Gun-toting humanoid robot sent into space

Russia has launched a humanoid robot into space on a rocket bound for the International Space Station (ISS). The robot Fedor will spend 10 days aboard the ISS practising skills such as using tools to fix issues onboard. Russia's deputy prime minister Dmitry Rogozin has previously shared videos of Fedor handling and shooting guns at a firing range with deadly accuracy.

Dmitry Rogozin/Twitter

2/25 Google turns 21

Google celebrates its 21st birthday on September 27. The The search engine was founded in September 1998 by two PhD students, Larry Page and Sergey Brin, in their dormitories at California’s Stanford University. Page and Brin chose the name google as it recalled the mathematic term 'googol', meaning 10 raised to the power of 100

3/25 Hexa drone lifts off

Chief engineer of LIFT aircraft Balazs Kerulo demonstrates the company's "Hexa" personal drone craft in Lago Vista, Texas on June 3 2019

Reuters

4/25 Project Scarlett to succeed Xbox One

Microsoft announced Project Scarlett, the successor to the Xbox One, at E3 2019. The company said that the new console will be 4 times as powerful as the Xbox One and is slated for a release date of Christmas 2020

Getty

5/25 First new iPod in four years

Apple has announced the new iPod Touch, the first new iPod in four years. The device will have the option of adding more storage, up to 256GB

Apple

6/25 Folding phone may flop

Samsung will cancel orders of its Galaxy Fold phone at the end of May if the phone is not then ready for sale. The $2000 folding phone has been found to break easily with review copies being recalled after backlash

PA

7/25 Charging mat non-starter

Apple has cancelled its AirPower wireless charging mat, which was slated as a way to charge numerous apple products at once

AFP/Getty

8/25 "Super league" India shoots down satellite

India has claimed status as part of a "super league" of nations after shooting down a live satellite in a test of new missile technology

EPA

9/25 5G incoming

5G wireless internet is expected to launch in 2019, with the potential to reach speeds of 50mb/s

Getty

10/25 Uber halts driverless testing after death

Uber has halted testing of driverless vehicles after a woman was killed by one of their cars in Tempe, Arizona. March 19 2018

Getty

11/25

A humanoid robot gestures during a demo at a stall in the Indian Machine Tools Expo, IMTEX/Tooltech 2017 held in Bangalore

Getty

12/25

A humanoid robot gestures during a demo at a stall in the Indian Machine Tools Expo, IMTEX/Tooltech 2017 held in Bangalore

Getty

13/25

Engineers test a four-metre-tall humanoid manned robot dubbed Method-2 in a lab of the Hankook Mirae Technology in Gunpo, south of Seoul, South Korea

Jung Yeon-Je/AFP/Getty

14/25

Engineers test a four-metre-tall humanoid manned robot dubbed Method-2 in a lab of the Hankook Mirae Technology in Gunpo, south of Seoul, South Korea

Jung Yeon-Je/AFP/Getty

15/25

The giant human-like robot bears a striking resemblance to the military robots starring in the movie 'Avatar' and is claimed as a world first by its creators from a South Korean robotic company

Jung Yeon-Je/AFP/Getty

16/25

Engineers test a four-metre-tall humanoid manned robot dubbed Method-2 in a lab of the Hankook Mirae Technology in Gunpo, south of Seoul, South Korea

Jung Yeon-Je/AFP/Getty

17/25

Waseda University's saxophonist robot WAS-5, developed by professor Atsuo Takanishi

Rex

18/25

Waseda University's saxophonist robot WAS-5, developed by professor Atsuo Takanishi and Kaptain Rock playing one string light saber guitar perform jam session

Rex

19/25

A test line of a new energy suspension railway resembling the giant panda is seen in Chengdu, Sichuan Province, China

Reuters

20/25

A test line of a new energy suspension railway, resembling a giant panda, is seen in Chengdu, Sichuan Province, China

Reuters

21/25

A concept car by Trumpchi from GAC Group is shown at the International Automobile Exhibition in Guangzhou, China

Rex

22/25

A Mirai fuel cell vehicle by Toyota is displayed at the International Automobile Exhibition in Guangzhou, China

Reuters

23/25

A visitor tries a Nissan VR experience at the International Automobile Exhibition in Guangzhou, China

Reuters

24/25

A man looks at an exhibit entitled 'Mimus' a giant industrial robot which has been reprogrammed to interact with humans during a photocall at the new Design Museum in South Kensington, London

Getty

25/25

A new Israeli Da-Vinci unmanned aerial vehicle manufactured by Elbit Systems is displayed during the 4th International conference on Home Land Security and Cyber in the Israeli coastal city of Tel Aviv

Getty

Their functionality and usage has since come a long way and in 2019 the trio of scientists credited with their development were awarded the Nobel Prize in Chemistry.

Nobel committee member Sara Snogerup Linse said lithium-ion batteries had granted access to “a technical revolution”.

The latest commercial potential for the technology is within electric planes, though the current energy density of lithium-ion batteries is roughly 2 per cent that of kerosene jet fuel.

The largest electric plane to have flown to date is a modified nine-seater Cessna, which achieved a 30 minute flight earlier this year.

Larger passenger jets are already under development, with budget airline EasyJet recently partnering with electric plane startup Wright Electric to build a prototype.

One of the key issues surrounding high-powered lithium-ion batteries is safety, having caused fires in Samsung smartphones and crashed Tesla cars in recent years.

“Because of the many incidents, safety has been at the top of minds in the industry,” said Mitalee Gupta, a senior analyst for energy storage at Wood Mackenzie.

“[APB’s battery] could be a breakthrough for both storage and electric vehicle applications, provided that the company is able to scale up pretty quickly.”

Earlier this year, APB raised 8 billion yen (£59bn) to equip a factory for mass production, which is scheduled to begin next year.

Africana55 Radio

Africana55 Radio